Scope

This information refers to silver tin

oxide wires, profiles and contact tips

manufactured by blending of silver

and metal oxide powder (SP) or with

additives (SPW), compacting, sintering,

extruding and drawing or rolling to

final dimensionaProfiles and tips are

available with a backing layer of silver

and optionalLy with an additional layer

of a brazing ahoy.

DESIGNATION OF

STANDARD COMPOSITIONS

The silver content is designated by the

first number e.g. Ag/Sn02 88/12 with

88 wt.-% silver, balance metal oxides.

The typical graduation of the latter are

8, 10 and 12. Additives improve the switching

behaviour of the different materials.

Applications

- contactors

- automotive relays

- powerline relays

- miniature circuit breakers

- switches for domestic applications

CHARACTERISTICS

- best anti-welding properties on make of

all silver metal oxide variants up to

currents of 5000A ( increasing with higher

oxide content)

- lowest erosion rate of all silver metal oxide

materials of currents exceeding 100 A

- significantly less material migration

compared to Ag/CdO and Ag/ZnO

- low contact resistance comparable to other

silver-metal oxides

- special additives keep the contact resistance

stable throughout the service life

- excellent arc extinguising properties,

better than Ag/CdO for currents upto 70 A

- free of toxic and carcinogenic components

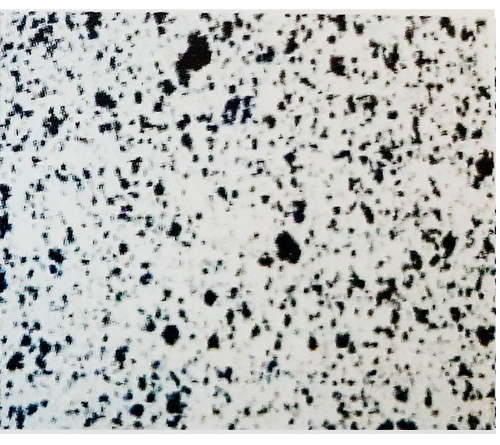

MICROSTRUCTURE

The micron sized Sn02 particles are oriented slightly

along the direction of extrusion.

Longitudinal Sectional

Ag/SnO

2 92/8 SPW

Longitudinal Section

Ag/SnO

2 88/12 SPW

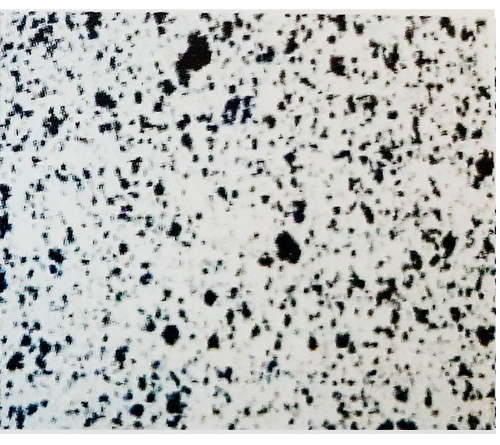

Cross Sectional

Ag/SnO

2 88/12 SPW

Physical Properties

| Material |

Ag/SnO2 92/8 SPW |

Ag/SnO2 90/10 SPW |

Ag/SnO2 88/8 SPW |

| Density [g/cm3] |

10.1 |

10.0 |

9.9 |

| Electrical Conductivity [m/(Ω.mm2)] |

48 |

47 |

45 |

| Hardness Soft [HV1] |

57 |

62 |

67 |

| Tensile Strenght Soft[Mpa] |

225 |

230 |

235 |

| Elongation [%] |

32 |

30 |

28 |

Longitudinal Sectional

Longitudinal Sectional Longitudinal Section

Longitudinal Section Cross Sectional

Cross Sectional