Bimetal Contact consist of soft, high-conductivity, oxidation-resistant materials used as the makeup of electrical components. They are the materials in a system through which an electrical current flows; such as:

- Circuit breakers

- Relays,

- Switches,

- EDM applications

- earth leakage breakers

Bimetal contact rivets comes in a variety of sizes. You can find options both small to extremely large, depending on your voltage requirements and usage.

Bimetal contact are typically made from any metal with high electrical conductivity. However, in applications such as high-power equipment where mechanical wear is expected, a conductive metal may be used. Common electrical contact materials include:

- Silver

- Copper

- Gold

- Platinum

- Palladium

- Brass

Bimetal Contact Material Properties

When choosing the best Bimetal contact for your application, it is important to keep in mind the six most important properties:

- Conductivity

- Corrosion Resistance

- Hardness

- Current Load

- Cycle Life

- Size

Bimetal Contact Conductivity

Conductivity refers to the measure of a materials ability to conduct or carry an electric current. You will see this as a percent of a copper standard (ex: 100% International Annealed Copper Standard or IACS) Silver, which has the highest conductivity, has an IACS of 105.

Corrosion Resistance

Corrosion resistance of electrical contacts refers to a material’s ability to resist chemical decay. Any material with little corrosion resistance will decay faster than ones with high resistance. Hardness

This measures how resistant materials are to various kinds of permanent deformations from an applied force. It is dependant on five factors:

- Ductility

- Elasticity

- Plasticity

- Tensile Strength

- Toughness

Alloys composition

- Silver Cadmium Oxide

- Silver Graphite

- Silver Tin Oxide

- Silver Nickel

Scope

This information refers to silver cadmium oxide wires, profiles and contact tips manufactured by blending of silver and cadmium oxide powder,cornpacting, sintering, extruding and then drawing or rolling to final dimension. Profiles and tips are available with a brazeable silver backing layer.

DESIGNATION OF STANDARD COMPOSITIONS

The silver content is designated by the first number: e.gAg/CdO 88/12 with 88 wt.-% silver, balance CdO. The standard oxide contents are 10,12 and 15.

Applications

- switches for domestic applications, main switches

- earth leakage breakers, miniature circuit breakers

- contactors

- circuit breakers up to a switching current of 3000 A

- power Line relays

CHARACTERISTICS

- excellent anti-welding properties on make, higher CdO content is improving anti-welding properties

- low contact resistance compared to other metal oxides

- contact resistance stable throughout the time life

- low arc erosion,excellent arc extinguishing properties

- tendency for material transfer in DC applications

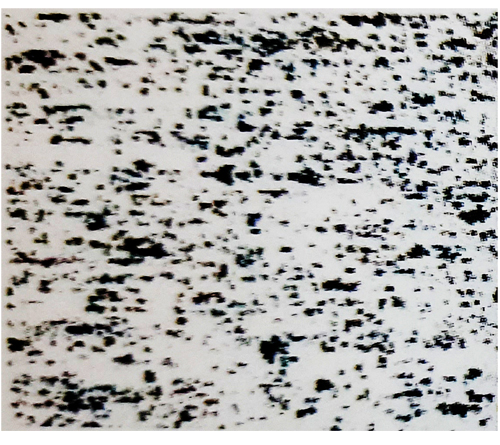

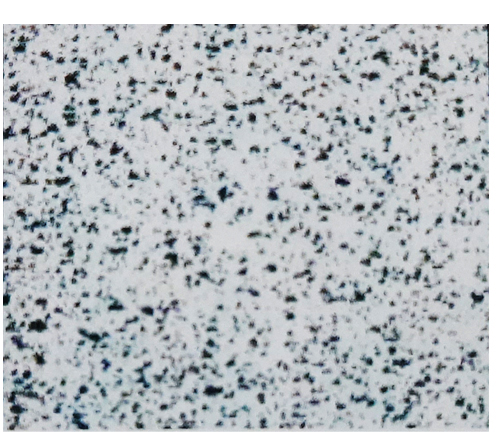

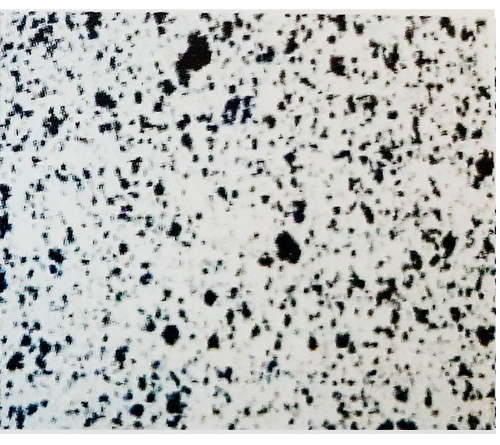

MICROSTRUCTURE

The nature of our Production process leads to a certain orientation of the CdO particles along the direction of extrusion.

Longitudinal Sectional

Ag/CdO 90/ 10 SP

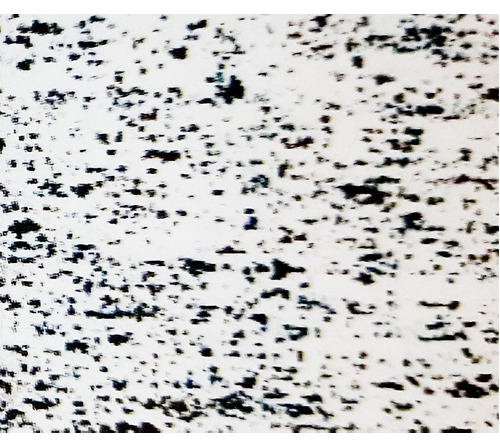

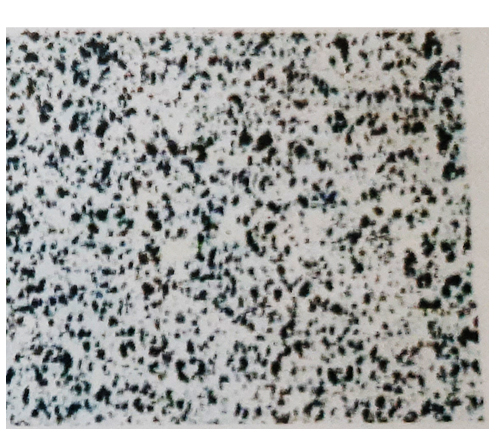

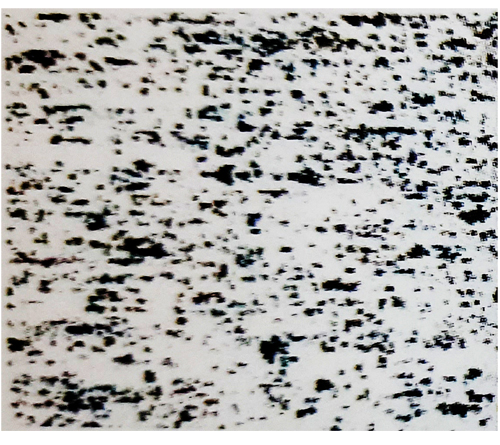

Cross Section

Ag/CdO 90/ 10 SP

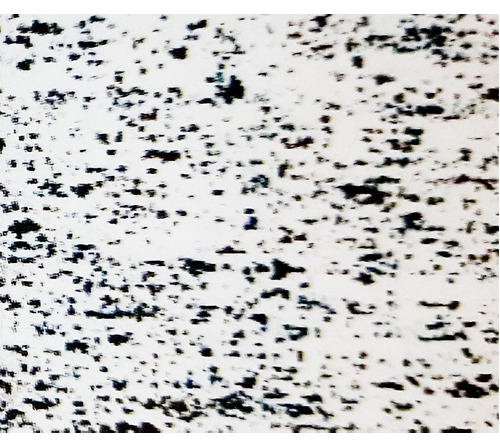

Longitudinal Sectional

Ag/CdO 85/ 15 SP

Physical Properties

| Material | Ag/CdO 90/ 10 SP | Ag/CdO 90/ 10 SP | Ag/CdO 85/ 15 SP |

| Density [g/cm3] | 10.2 | 10.1 | 10.0 |

| Electrical Conductivity [m/(Ω.mm2)] | 48 | 47 | 45 |

| Hardness Soft [Mpa] | 50 | 60 | 65 |

| Tensile Strenght Soft[Mpa] | 240 | 250 | 260 |

| Elongation [%] | 30 | 29 | 25 |

Scope

This information refers to silver graphite profiles and contact tips manufactured by blending of silver and graphite powder, compacting, sintering, extruding and rolling. The deformation results in the alignment of graphite particles along the direction of the extrusion and rolling. A brazeable silver side is produced by decarburization. Profiles clad with a brazing alloy and presoldered contact tips are available.

DESIGNATION OF STANDARD COMPOSITIONS

Profiles show a parallel orientation of the graphite to the contact surface and can be produced with 2 and 3 weight percent graphite. contact tips with 2,3,4 and 5% are available either with the parallel orientation (AgC II) or with a perpendicular orientation of the graphite to the contact surface (AgC!)

Applications

- circuit breakers

- earth leakage breakers

- miniature circuit breakers

CHARACTERISTICS

- best anti-welding properties of all contact materials on make with C-contents of 3% and higher (better with graphite particle alignment parallel to contact side)

- best protection against contact welding of closed contacts under short ciruit currents

- low erosion on make

- low contact resistance

- reduced erosion on break with perpendicular graphite particle alignment to contact surface

- inferior are migration properties; compensated by asymmetrical material combinations:

- Cu counter-contact with low currents

- AgNi counter-contact with high currents

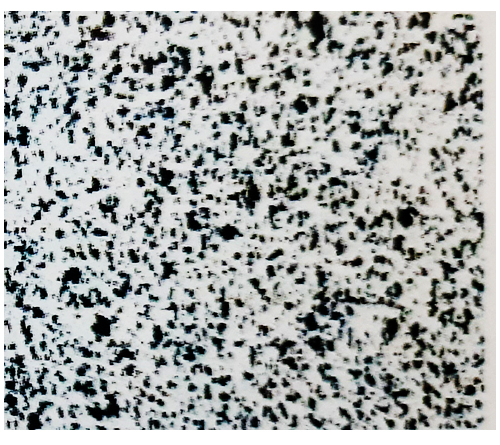

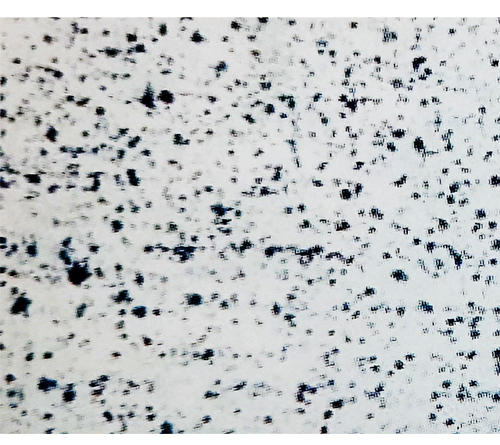

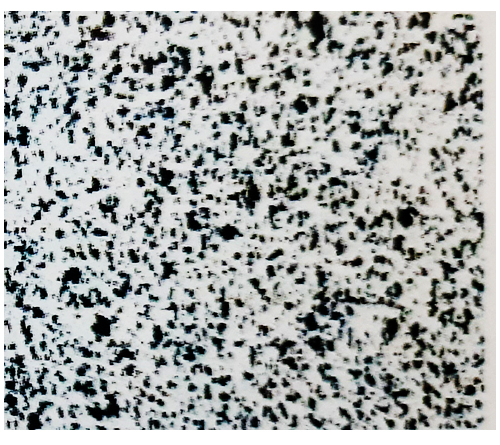

MICROSTRUCTURE

The directional deformation of the material during the manufacturing process causes a strong displacement of the graphite particles into graphite layers.

Longitudinal Sectional

(parallel to the diretion of extrusion)

AgC

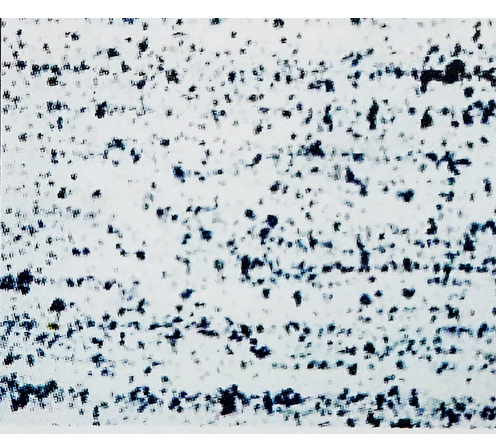

3 Cross Section

AgC

5 Cross Section

Physical Properties

| Material | AgC2 | AgC3 | AgC4 | AgC5 |

| Density [g/cm3] | 9.4 | 9.1 | 8.8 | 8.6 |

| Electrical Conductivity [m/(Ω.mm2)] | 47 | 47 | 44 | 43.5 |

| Hardness Soft [HV1] | 35 | 35 | 35 | 35 |

Scope

This information refers to silver tin oxide wires, profiles and contact tips manufactured by blending of silver and metal oxide powder (SP) or with additives (SPW), compacting, sintering, extruding and drawing or rolling to final dimensionaProfiles and tips are available with a backing layer of silver and optionalLy with an additional layer of a brazing ahoy.

DESIGNATION OF STANDARD COMPOSITIONS

The silver content is designated by the first number e.g. Ag/Sn02 88/12 with 88 wt.-% silver, balance metal oxides. The typical graduation of the latter are 8, 10 and 12. Additives improve the switching behaviour of the different materials.

Applications

- contactors

- automotive relays

- powerline relays

- miniature circuit breakers

- switches for domestic applications

CHARACTERISTICS

- best anti-welding properties on make of all silver metal oxide variants up to currents of 5000A ( increasing with higher oxide content)

- lowest erosion rate of all silver metal oxide materials of currents exceeding 100 A

- significantly less material migration compared to Ag/CdO and Ag/ZnO

- low contact resistance comparable to other silver-metal oxides

- special additives keep the contact resistance stable throughout the service life

- excellent arc extinguising properties, better than Ag/CdO for currents upto 70 A

- free of toxic and carcinogenic components

MICROSTRUCTURE

The micron sized Sn0

2 particles are oriented slightly along the direction of extrusion direction of extrusion.

Longitudinal Sectional

Ag/SnO

2 92/8 SPW

Longitudinal Section

Ag/SnO

2 88/12 SPW

Cross Sectional

Ag/SnO

2 88/12 SPW

Physical Properties

| Material | Ag/SnO2 92/8 SPW | Ag/SnO2 90/10 SPW | Ag/SnO2 88/8 SPW |

| Density [g/cm3] | 10.1 | 10.0 | 9.9 |

| Electrical Conductivity [m/(Ω.mm2)] | 48 | 47 | 45 |

| Hardness Soft [HV1] | 57 | 62 | 67 |

| Tensile Strenght Soft[Mpa] | 225 | 230 | 235 |

| Elongation [%] | 32 | 30 | 28 |

Scope

This information refers to silver nickel wires, profiles and contact tips manufactured by blending of silver and nickel powder, compacting,sintering, extruding and drawing or rolling to final dimension.

DESIGNATION OF STANDARD COMPOSITIONS

the Ni content of the material is designated in weight percentage.

Standard gradations are 10, 15, 20%.

Applications

- switches for domestic applications, main switches

- switches for domestic application, auxiliary switches

- contactors of switching currents upto 100A

- miniature circuit breakers, circuit breakers (asymmetrical combination with AgC)

- power line relays, automotive relays

CHARACTERISTICS

- reliable anti-welding properties for switching currents upto 100A

- low contact resistance (nearly constant throughout the life time)

- low arc erosion for switching current upto 100A

- good arc migration and arc extinguishing properties

- good formability, can be welded directly

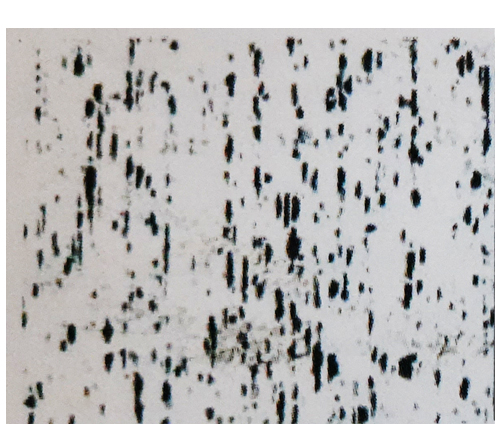

MICROSTRUCTURE

The Ni particles are deformed along the direction of extrusioii into fibres

AgNi10

Longitudinal Sectional (parallel to the diretion of extrusion)

AgNi10

Cross Section

AgNi20

Cross Section

Physical Properties

| Material | AgNi10 | AgNi15 | AgNi20 |

| Density [g/cm3] | 10.3 | 10.2 | 10.1 |

| Electrical Conductivity [m/(Ω.mm2)] | 54 | 48 | 46 |

| Hardness Soft [HV1] | 50 | 55 | 60 |

| Tensile Strenght Soft[Mpa] | 240 | 260 | 270 |

| Elongation [%] | 38 | 34 | 32 |

Our Bimetal Contact Rivets includes Bimetal Contact Rivets, Bimetal Contacts, Electrical Bimetal Contacts, Silver Bimetal Contact Rivets, Bimetal Electrical Contact Rivets, Contact Rivets, Cold Headed Electrical Bimetal Contacts, Electrical Silver Bimetal Contact Rivets, Bimetal Rivet, AgNi Bimetal Contact Rivets, Electrical Contact Rivets, Electrical Contacts, Electrical Contact Rivet Silver, Silver Contact Pins Used in Relay, OEM Tungsten Contact Point for Horn, AgNi Copper Bimetal Trimetal Solid Silver Alloy Electrical Contact Rivets, Silver Electric Copper Contact Points, Cold Headed Electrical Contacts Bimetal and Solid Rivets, Silver Electrical Bimetal Contact Rivets, AgNi AgSnO2 AgCdO Bimetal Silver Contact Tip, Electrcial AgSnO2 Silver Copper Composite Contact Rivet for Relay Switch, Electrical Stamping Parts Riveting Silver Contact for Switches, AgC Silver Powder Alloy Tips, AgNi10/Cu Bimetal Silver Contact Points for Wall Switches, Tungsten Electrical Contact Point for Car Horn, Electrical Stamping Parts, Contact Components for Switch and Socket, Solid Electrical Silver Rivet, Au Gold Plating Electrical Contacts for 40A Switch, 4mm Electrical Contact Copper Tungsten Point, Rivetting Point, agzno Electrical Contact, Silver Plated Bimetal Rivet, Bimetal Contact Silver Rivets, Moving Bimetal Contact Rivets, Bimetal Trimetal Silver Contacts, Rivets Silver Alloy Electrical, Riveting Contacts, Silver Electrical Contact Rivets, Contact Rivets Electrical, Contact Tungsten Electrical, Cu AgSnO2 Bimetal Silver Contact Rivets, Trimetal Silver Contact Rivets, Silver Bimetal Contact, Electrical Switch Bimetal Contacts, Electrical Switch trimetal Contacts, bimetal contact, contact tips, trimetal contact, silver alloy wire, electrical contact tips, electrical switch contacts, iron tungsten contact, contacts assembly, bimetal capsule contact, copper rivets contact, switch contact, contact tip welding, mig contact tip, mig welding contact tips, nickel silver wire, contact tip mig, tip contact, bimetal contact rivets, copper silver wire, Electrcial Contact Material, Rivet Contacts, Silver Electrical Contacts, Powder Metallurgy Contact Tip, Contact Tips For Relay, customized Contact Tips, Gold Plated Electrical Contact Tips, Electric silver contact tip, copper tungsten electrical contact, silver contact rivet, electric switch contact, Silver Carbon contact tips, bimetal tip, Contact tip for welding robot, CO2 Copper Contact Tips, Chrome zirconium copper Panasonic contact tip, Brass Welding Contact Tip, COPPER WELDING CONTACT TIP, electrical tungsten silver rivet, Bimetal Rivet Silver Contact For Relay And Starter Switch, Silver Electrical Contact Disc, AgCdo electric wedling braze silver contact tip, Silver contact tip, Electrical silver contacts, Electrical Contact Rivets, Mig Contact Tips, Silver Solid Tip, Silver contact, Electrical Contact Rivets, Copper Composite Rivets, mig soldering contact tip, biemtal silver contact tip for riveting, contact spring bridge, silver solid tip, Tungsten tip, contact finger, Electrical Contact Tips, Silver Contact Rivet, Trimetal Rivet