Scope

This information refers to silver graphite

profiles and contact tips manufactured by

blending of silver and graphite powder,

compacting, sintering, extruding and rolling.

The deformation results in the alignment

of graphite particles along the direction

of the extrusion and rolling. A brazeable

silver side is produced by decarburization.

Profiles clad with a brazing alloy and

presoldered contact tips are available.

DESIGNATION OF

STANDARD COMPOSITIONS

Profiles show a parallel orientation of the

graphite to the contact surface and can be

produced with 2 and 3 weight percent

graphite. contact tips with 2,3,4 and 5% are

available either with the parallel orientation

(AgC II) or with a perpendicular orientation

of the graphite to the contact surface (AgC!)

Applications

- circuit breakers

- earth leakage breakers

- miniature circuit breakers

CHARACTERISTICS

- best anti-welding properties of all contact

materials on make with C-contents of 3%

and higher (better with graphite particle

alignment parallel to contact side)

- best protection against contact welding

of closed contacts under short ciruit

currents

- low erosion on make

- low contact resistance

- reduced erosion on break with

perpendicular graphite particle alignment to contact surface

- inferior are migration properties; compensated by

asymmetrical material combinations:

- Cu counter-contact with low currents

-

AgNi counter-contact with high currents

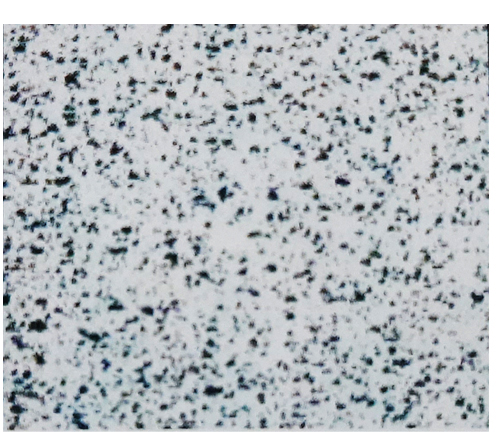

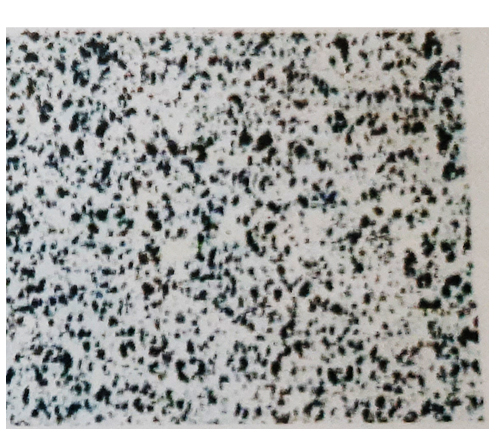

MICROSTRUCTURE

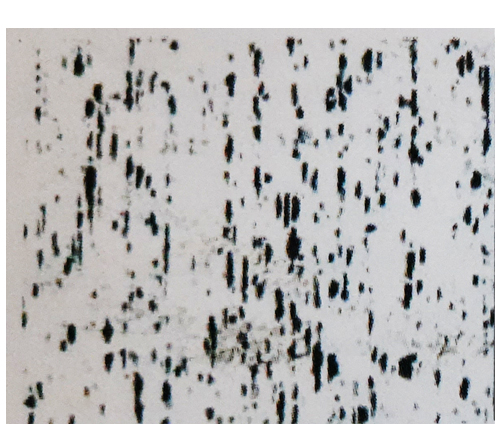

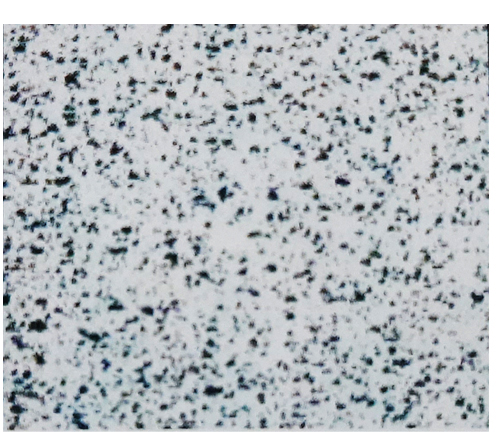

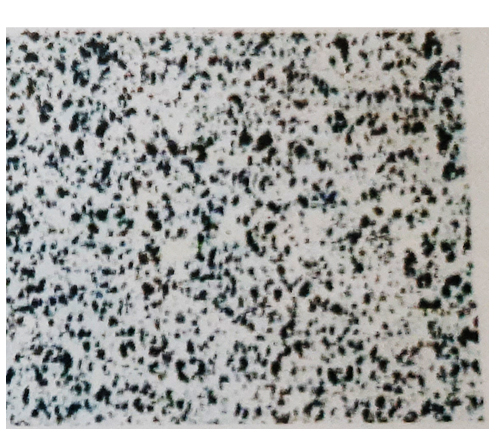

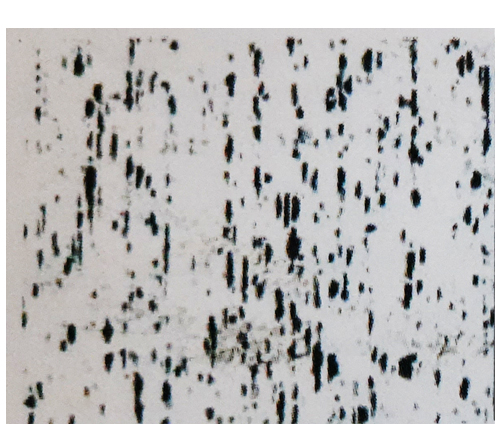

The directional deformation of the material during the

manufacturing process causes a strong displacement of

the graphite particles into graphite layers.

Longitudinal Sectional

(parallel to the diretion

of extrusion)

AgC

3

Cross Section

AgC

5

Cross Section

Physical Properties

| Material |

AgC2 |

AgC3 |

AgC4 |

AgC5 |

| Density [g/cm3] |

9.4 |

9.1 |

8.8 |

8.6 |

| Electrical Conductivity [m/(Ω.mm2)] |

47 |

47 |

44 |

43.5 |

| Hardness Soft [HV1] |

35 |

35 |

35 |

35 |

Longitudinal Sectional

Longitudinal Sectional AgC3

AgC3 AgC5

AgC5